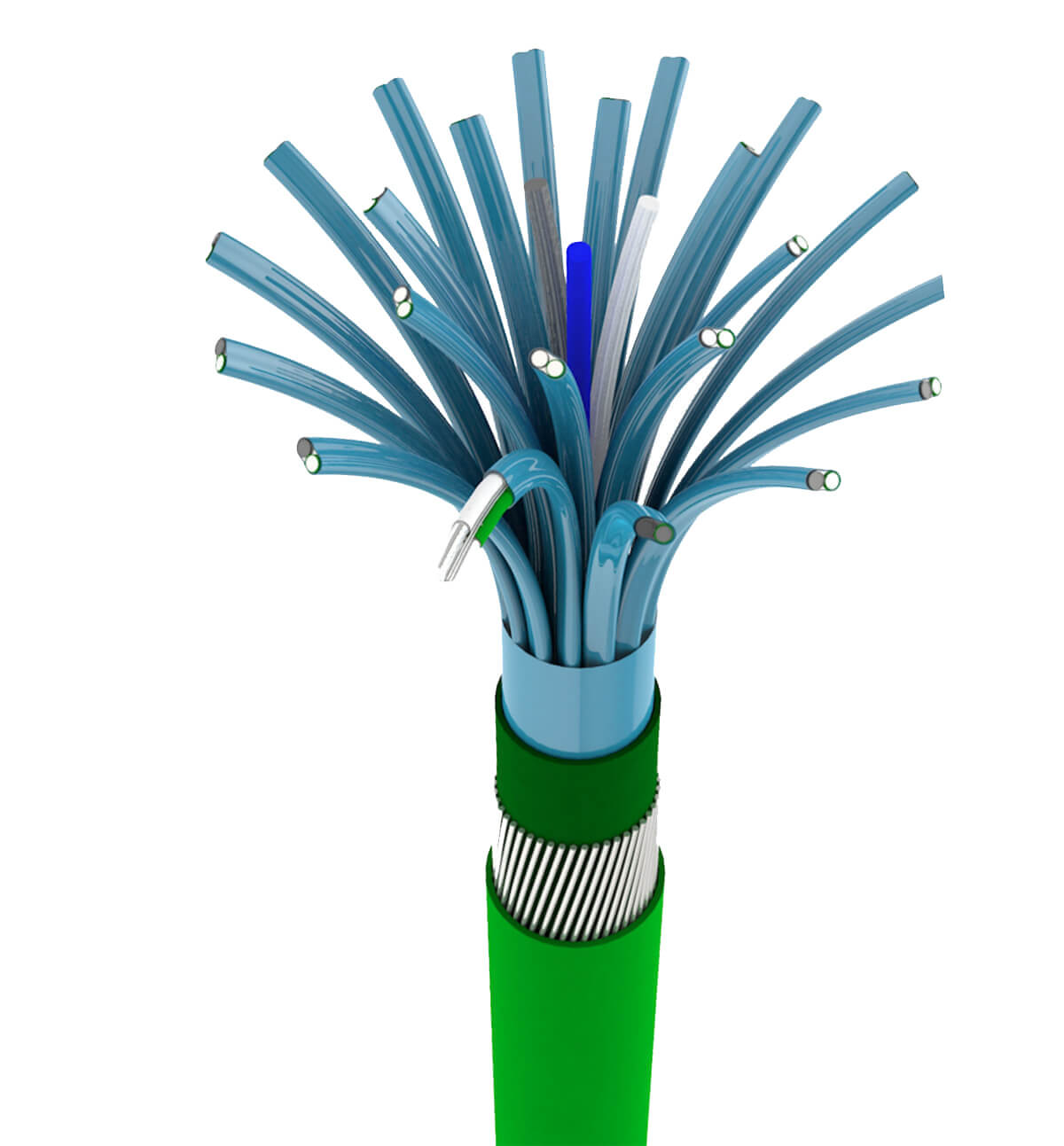

Cables

Discover the exceptional quality of

specialized cables designed

for industrial applications,

temperature sensors, and beyond,

merging experience with innovation.

Applications

Elevate your projects with

our specialty cables, known

for their reliability and high

performance across

diverse industrial sectors.

Services

A comprehensive suite of

services tailored to fulfill

our clients' unique requirements.

About

Your trusted partner for all your cable needs

Siccet USA delivers advanced cable solutions for temperature sensors and specialty applications, combining exceptional quality, technical expertise, and responsive service to meet market demands for reliability and long-term performance.

Discover moreProvider of specialty cables

Products

Applications

Tailored solutions to address every specific need

Discover moreMaterials

Top-Grade Materials for Superior Performance

Our cables are designed with high-quality insulating materials and sheaths, engineered for exceptional durability and reliability. These advanced materials ensure optimal performance, tailored to the specific demands of each application.

Discover more